A Critical Solution for Sensitive Environments

In today’s technology-driven world, electrostatic discharge (ESD) poses a hidden but significant threat across many industries. Whether it’s damaging delicate electronic components or igniting flammable materials, static electricity is a real risk—one that many facilities can’t afford to ignore. That’s why Electrostatic Dissipative (ESD) epoxy flooring has become a vital solution in environments where safety, precision, and reliability are non-negotiable.

Why Facilities Require ESD Flooring

Electrostatic discharge occurs when two differently charged materials come into contact or close proximity, resulting in a sudden transfer of electricity. While often unnoticed, ESD can have major consequences:

- Electronics Manufacturing: Even a static discharge as low as 10 volts can damage semiconductors or printed circuit boards (PCBs), leading to latent defects or total failure.

- Cleanrooms & Labs: Static can attract dust particles, compromise sterile environments, and disrupt sensitive testing equipment.

- Explosive or Flammable Environments: A single spark can trigger combustion, especially in plants that use aluminum powder, chemicals or munitions facilities.

- Healthcare & Medical Device Manufacturing: ESD can damage life-critical instruments or cause malfunction during calibration or assembly.

In each of these cases, static control is not just a performance issue—it’s a safety and liability concern.

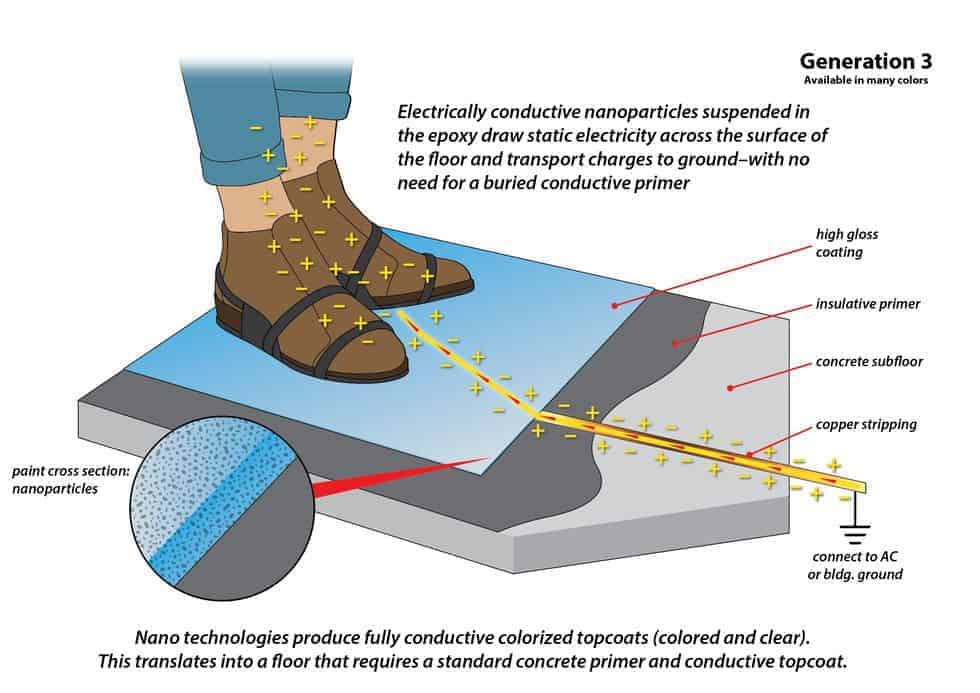

How does ESD Epoxy Flooring Help? ESD epoxy flooring systems are specifically engineered to reduce the accumulation and discharge of static electricity. Here’s how they provide protection:

Controlled Electrical Resistance

ESD epoxy coatings are formulated with conductive or dissipative materials that channel static charges safely into the ground. This keeps the floor’s surface resistance within a precise range—typically between 1×10⁶ and 1×10⁹ ohms—enough to prevent buildup but not so conductive as to be unsafe for workers.

It’s important to continue testing the ESD epoxy floors, and every ESD floor operator should have a megohmmeter on hand to test the ohms ranges on the floors. One interesting note, as the epoxy cures, the material increases in hardness, creating a more conductive surface. In our own testing, our megohmeters have shown that the resistance levels decrease over time, allowing the floors to improve their dissipative properties.

Durable, Seamless Protection

Unlike mats or floor coverings that wear out or shift, ESD epoxy flooring forms a seamless, bonded surface that maintains its dissipative properties over time. The conductive material within the coating doesn’t degrade, and will continue to perform as long as the ESD coating is intact and grounded. These floors can withstand:

- Heavy traffic

- Equipment loads

- Chemical exposure

- Frequent cleaning

Compliance and Certification

High-quality ESD epoxy systems can help facilities comply with industry standards such as:

- ANSI/ESD S20.20

- ASTM F150 (for electrical resistance)

- IEC 61340-5-1

This is essential for companies operating under strict quality assurance protocols, including aerospace, automotive electronics, and pharmaceuticals.

Customization and Integration

ESD epoxy floors can be customized to meet both performance and aesthetic needs:

- Gloss or satin finishes

- Safety striping or walkways

- Anti-slip textures

- Integration with grounded systems

Industries That Benefit from ESD Epoxy Floors

- Electronics and Semiconductor Manufacturing

- Cleanrooms and Biotech Labs

- Aerospace and Defense Facilities

- Battery Production

- Medical Device Manufacturing

- Data Centers and Server Rooms

- Chemical and Pharmaceutical Plants

In environments where electrostatic discharge poses operational, financial, or safety risks, ESD epoxy flooring offers a permanent and reliable solution. These specialized floors not only protect equipment and personnel but also support regulatory compliance and process integrity.

If your facility handles sensitive electronics, volatile chemicals, or mission-critical systems, ESD flooring isn’t just a nice-to-have—it’s a must-have.

Written By, Jeff Neal [Division Manager, Concrete Coatings Department, at The Witmer Group]

linkedin.com/in/installingepoxyfloors