Your facility’s floors take the most abuse in your building. Forklift traffic, construction equipment, harsh cleaners, and heavy industrial operations challenge them every day. That’s why asking the right questions is essential to choosing the best flooring application for your plant.

Do you need a slip-resistant and colorful surface? Epoxy and urethane coatings offer the best solution. Prefer something low-maintenance that still reflects light and stays dust-free? Concrete polishing might suit your needs better.

Here’s a quick breakdown to help you decide between epoxy coatings and polished concrete:

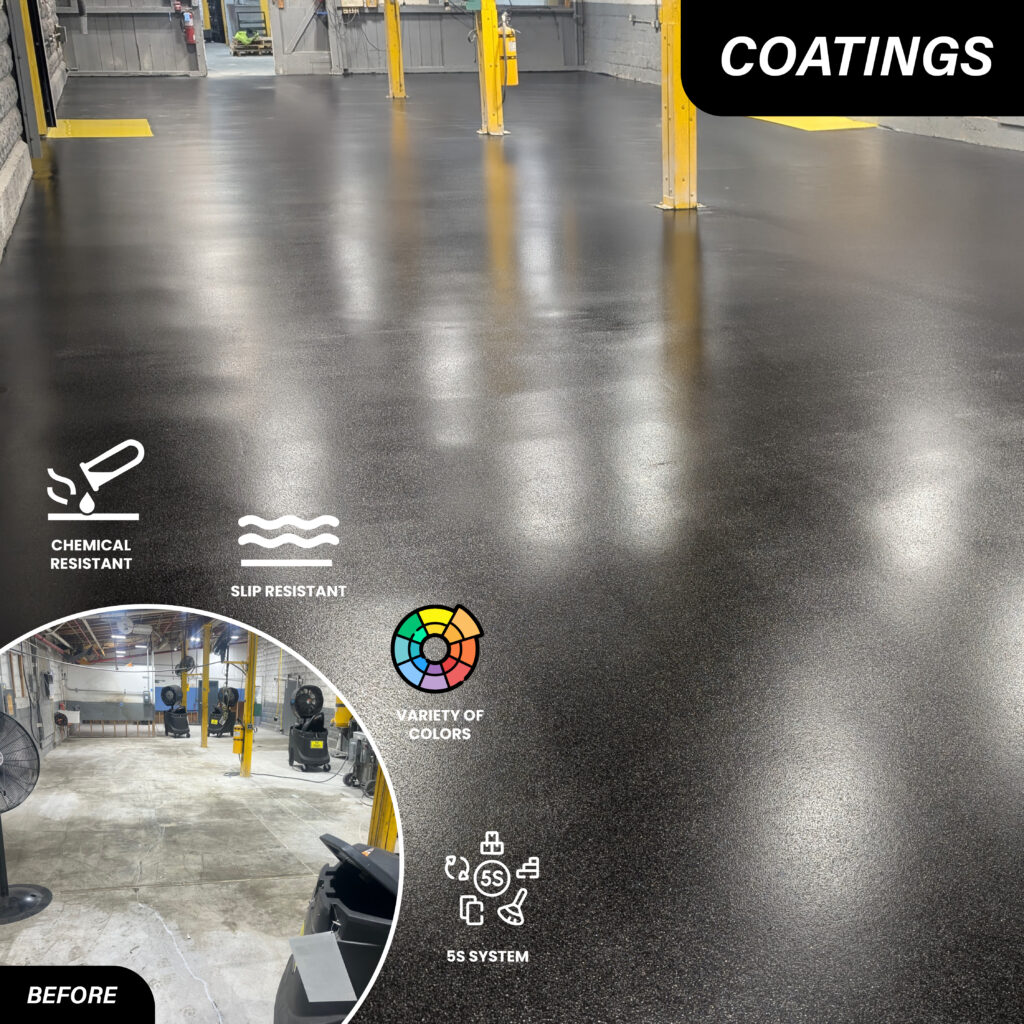

Industrial Epoxy Coatings

Epoxies and urethanes remain the most commonly used materials in commercial and industrial buildings. These coatings support daily operations with several key benefits:

-

Chemical Resistance – Many plants handle acidic and caustic cleaners, hydraulic fluid, and other corrosive substances. These liquids can eat through the concrete slab—a structural element of your facility. To prevent this, we review the SDS for all your cleaners and materials to ensure the right chemical-resistant topcoat goes in the right areas.

-

Slip Resistance – Washrooms, food processing rooms, and similar spaces require regular washing. While critical for sanitation, wet floors increase safety risks. Slip-resistant coatings improve safety by adding texture using quartz sand, glass beads, or aluminum oxide. Coatings remain the only effective way to achieve true slip resistance.

-

5S and Visual Workplaces – Adding color to your floors boosts visibility for both safety and 5S organizational systems. Bright colors help guide pedestrian traffic and keep footpaths safe. Color-coded floor zones also help staff stay organized by visually showing where things belong.

Polished Concrete

Choose polished concrete in areas where you don’t need chemical resistance, slip resistance, or added color. Keep in mind: harsh cleaners will corrode polished floors, and wet surfaces can become slippery—similar to a basketball court. However, polished concrete still offers many advantages:

-

Easy Maintenance – The polishing process densifies and seals the slab’s surface, making it smooth, tight, and nearly dust-free. These easy-to-clean floors work well in clean zones.

-

No Chipped Coatings – Because polished concrete doesn’t use coatings, it won’t peel or chip. Forklift operators often damage coated floors, leading to delamination. You can avoid that issue entirely with polished floors, making them ideal for high-traffic areas.

-

Reflectivity – Polished concrete enhances a room’s brightness without relying on high-gloss coatings. The natural reflectivity supports energy efficiency and visibility.

In the end, let your cleaning schedule and room function guide your decision. Both epoxy coatings and polished concrete offer distinct benefits depending on how you use the space.

Written By, Jeff Neal [Division Manager, Concrete Coatings Department, at The Witmer Group]