Concrete Repair & Maintenance

Bringing a concrete floor back to its original state is critical to the safety and productivity of your facility. Not addressing deterioration issues can potentially cost lost time and efficiency. The Witmer Group investigates to help determine the causes of deterioration and will recommend only the most appropriate materials to make repairs. We follow through with the techniques necessary to achieve the most durable floor.

Typical types of declines or failures where we provide solutions:

Curling slab edges, rocking slabs, slab corner breaks, cracks, gouges, spalled joints and joint fill separation and spalling/gouges:

These are maintenance issues that need to be addressed to prevent costly repairs and more importantly can also cause injury and damage to equipment.

Joint fill separation:

With continued use, the separated fill will become more recessed, the spalling will spread outward from the joints, and the chips at the corners will grow.

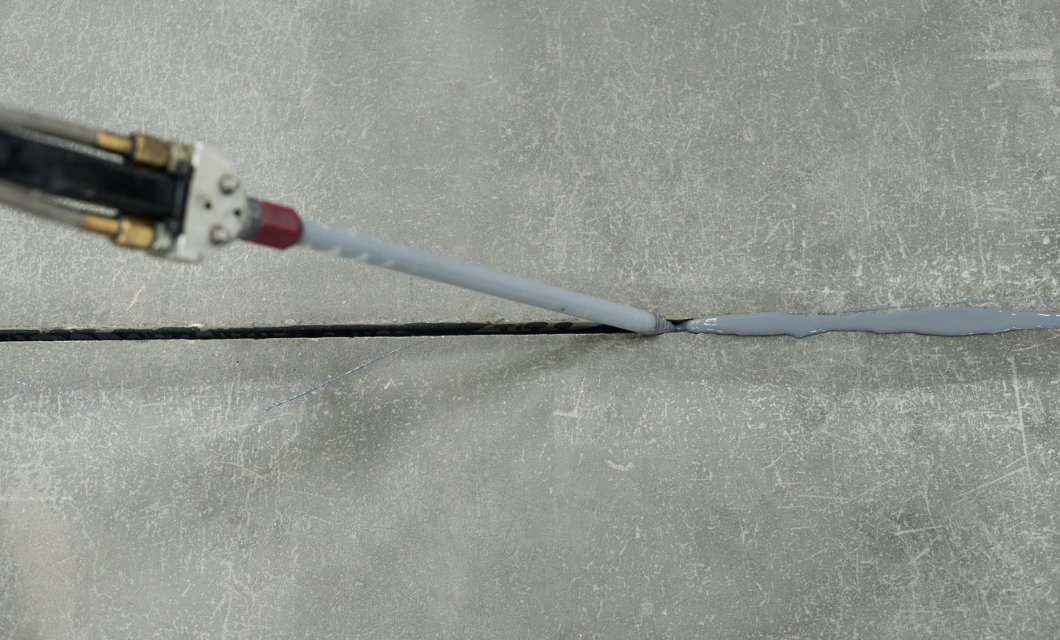

Cracks:

Cracks happen for a number of reasons. Although the repair can be straightforward, it’s imperative to understand the root cause of the problem, as there may be an underlying issue requiring priority attention.

Watch our industrial concrete floor repair services video here:

Why Witmer? Because repairing your floor for durability requires more than a quick fix. It requires qualified restoration.

Our Process

We'll start by determining the cause of the deterioration. Low filler profile; poor joint cleaning prior to filling; the wrong filler; no filler; differing slab elevations (creating slab curl); rocking slab conditions (result of subgrade deficiencies or voids) - establishing cause is necessary to properly repair the defect.

We select the appropriate repair materials. Frequency of traffic, vehicle loading and vehicle types, building temperatures, dry/cure time available, the width of the defect, and the structural condition of the floors all determine what materials are best to use. Choose the wrong material and the results will not be durable nor lasting.

We'll define the edges, and clean properly. The #1 cause of joint failure is inadequate preparation. Edges must be ground to a minimum of 1/2" deep vertically, thoroughly cleaned and dry to ensure long-term durability and structural stability of the repair.

Your finished repair is flush with the floor. Without smooth and continuous transitions repairs will not last. We overfill slightly, allow the material to cure into a solid, then shave or grind flush the overfill. A concave or "dished" repair/filler profile leaves joint edges exposed as impact points, and thus subject to deterioration under hard-wheeled traffic.

Featured Project

Concrete Repair & Maintenance

100 Gea Drive

A large 272,787 SF facility was in need of concrete floor repair. The work was completed before the installation of equipment to provide a stable surface that would allow for material handling vehicles to run effectively.

© Witmer Group 2026 All Rights Reserved. | Site Map | Privacy Policy